In any industrial project, selecting the appropriate material is one of the most critical decisions. Previously, we have provided detailed guidance on how to select the perfect titanium grade for your industry applications. Among the most widely used materials, titanium and stainless steel both stand out for their durability, mechanical strength, and corrosion resistance. However, the performance of these two materials varies significantly under different conditions—choosing the wrong material can impact product lifespan, maintenance costs, and overall project efficiency.

This guide breaks down the strength, weight, corrosion resistance, cost, and industrial applications of titanium and stainless steel to help engineers, manufacturers, and procurement teams make an informed choice.

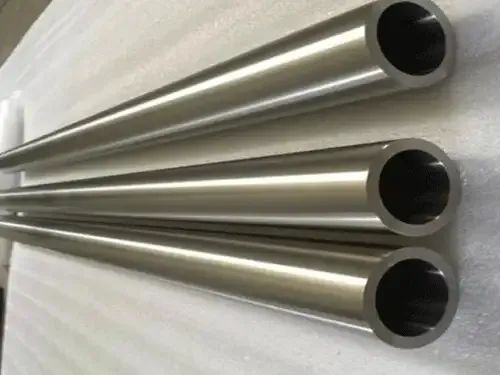

Titanium: High Strength with Ultra-Lightweight Advantage

Titanium is globally recognized for its exceptional strength-to-weight ratio. It delivers near-steel strength while being up to 45% lighter, making it ideal for industries that require high performance without extra weight load.

Common applications: aerospace components, marine equipment, heat exchangers, precision machinery.

Stainless Steel: Strong, Stable, and More Cost-Friendly

Although heavier, stainless steel offers consistent structural strength and is widely used where weight is not the primary concern. It is also available in numerous grades that suit both high-strength and general-purpose applications.

Common applications: construction, food machinery, piping systems, automotive parts.

Both materials resist corrosion, but their performance differs dramatically under harsh conditions.

Titanium: Outstanding Chemical & Seawater Resistance

Titanium forms a natural protective oxide layer, allowing it to withstand:

Highly corrosive chemicals

Acidic environments

High-temperature oxidation

Long-term seawater exposure

This makes titanium a preferred choice in chemical processing, desalination plants, and offshore applications.

Stainless Steel: Reliable but Sometimes Requires Protection

High-grade stainless steels like 304 and 316 offer excellent corrosion resistance. However, in extremely acidic or chloride-rich environments, pitting and crevice corrosion may occur without additional coatings or maintenance.

Titanium: Higher Cost, Higher Performance

Titanium’s price is significantly higher—not just in raw material, but also in processing:

Requires specialized machining tools

Welding and forming procedures are more complex

Lead times may be longer

Titanium is best for high-value industries where performance outweighs cost.

Stainless Steel: Cost-Effective & Easy to Fabricate

Stainless steel is:

More economical

Readily available in many forms

Easy to cut, weld, and machine

Ideal for mass production

This makes stainless steel the go-to material for large-scale industrial manufacturing.

Titanium Applications

Aerospace & aviation parts

Heat exchangers & condensers

Chemical processing tanks & valves

Marine components

Medical implants and high-performance tools

Titanium is selected when low weight, high strength, and high corrosion resistance are essential.

Stainless Steel Applications

Food & beverage machinery

Pharmaceutical equipment

Building structure components

Oil & gas pipelines

Automotive and mechanical parts

Stainless steel is ideal for cost-sensitive projects requiring durability and hygiene.

Your final choice should consider these factors:

|

Requirement |

Best Choice |

Reason |

|

Lightweight but strong |

Titanium |

High strength-to-weight ratio |

|

Extreme corrosion environments |

Titanium |

Superior chemical & seawater resistance |

|

Low budget or large-volume production |

Stainless steel |

More economical and easier to fabricate |

|

General industrial machinery |

Stainless steel |

Versatile and widely available |

|

Chemical, aerospace, or marine industries |

Titanium |

High performance in demanding environments |

Both titanium and stainless steel are excellent industrial materials—but they shine in different scenarios.

Choose titanium when you need top-tier performance, low weight, and extreme corrosion resistance.

Choose stainless steel when cost, availability, and fabrication ease are your priorities.

By understanding their distinct properties, industrial professionals can select the material that delivers the best balance of performance, durability, and cost-effectiveness for their specific application.

Share this page

If you have any product needs or questions, please leave us a message for consultation.

TEL: 86-18623759992

jason@bettmetal.com

Innovating Materials

for a Brighter Future