Tungsten has long been valued as a critical industrial metal, prized for its exceptional hardness, ultra-high melting point, and remarkable wear resistance. With industries pushing for high-performance materials, tungsten’s role has expanded in sectors ranging from aerospace and defense to electronics, automotive, and industrial machinery.

Among the many ways to process tungsten, powder metallurgy (PM) has emerged as the industry standard. It offers precision, cost efficiency, and material utilization that traditional melting and casting cannot match.

This guide dives deep into the tungsten PM process—from raw powder to finished components—helping engineers, procurement specialists, and decision-makers understand exactly how tungsten parts are made and why PM is the preferred route.

Tungsten’s melting point of 3,422°C makes conventional melting or casting extremely difficult and costly. Powder metallurgy overcomes this by:

Shaping at room temperature and then sintering below melting point

Producing highly precise, dimensionally stable components

Reducing material loss and production cost

This approach allows manufacturers to create complex, high-performance parts that can withstand extreme environments without sacrificing reliability.

Unique Properties That Make Tungsten Ideal for PM

Powder metallurgy works best with metals that are hard to process by melting. Tungsten’s physical and chemical properties make it a perfect candidate:

Ultra-high melting point – performs reliably in high-temperature applications

High density (19.3 g/cm³) – ideal for counterweights, radiation shielding, and balancing systems

Outstanding hardness and wear resistance – ensures long-lasting performance

Low thermal expansion & high thermal conductivity – maintains stability under temperature changes

High-temperature strength & creep resistance – suitable for aerospace, defense, and industrial furnaces

These properties explain why tungsten PM is used in critical applications like missile components, high-speed cutting tools, and radiation protection equipment.

The quality of tungsten powder determines the final component’s performance, durability, and consistency. Production involves three key stages:

Ammonium Paratungstate (APT) Extraction

Tungsten ore is chemically processed to produce APT, the main intermediate for high-purity tungsten powder. The quality of APT directly affects particle uniformity and sinterability.

Hydrogen Reduction

APT is reduced to tungsten powder in a hydrogen reduction furnace. By controlling temperature, reduction rate, and hydrogen flow, manufacturers achieve precise particle size, morphology, and oxygen content.

Classification & Purification

The powder is sieved, purified, and tested for flowability, density, and chemical composition, ensuring it is ready for pressing and sintering.

Pro Tip: Finer, uniform powders improve sintering performance and mechanical strength, which is critical for aerospace and medical applications.

Once the powder is prepared, it is compacted into a “green body.” The method depends on the part size and complexity:

Cold Isostatic Pressing (CIP): Produces uniform density for large or intricate parts

Uniaxial Pressing: Fast and efficient for simple, high-volume shapes

Metal Injection Molding (MIM): Ideal for small, intricate components with complex geometries

Additive Manufacturing (AM): Emerging method for customized designs and lightweight components

Key insight: Higher green density generally results in better mechanical properties after sintering, which is why pressing uniformity is critical.

Sintering consolidates the green body at 1,600°C – 2,900°C, depending on composition and desired properties. During sintering:

Particles bond via diffusion

Pores shrink, increasing density

Mechanical strength, hardness, and thermal stability improve

Common sintering techniques include vacuum sintering, hydrogen sintering, and sometimes liquid-phase sintering with alloying elements for high-density, high-strength parts.

Powder metallurgy enables the production of high-performance tungsten products across multiple industries:

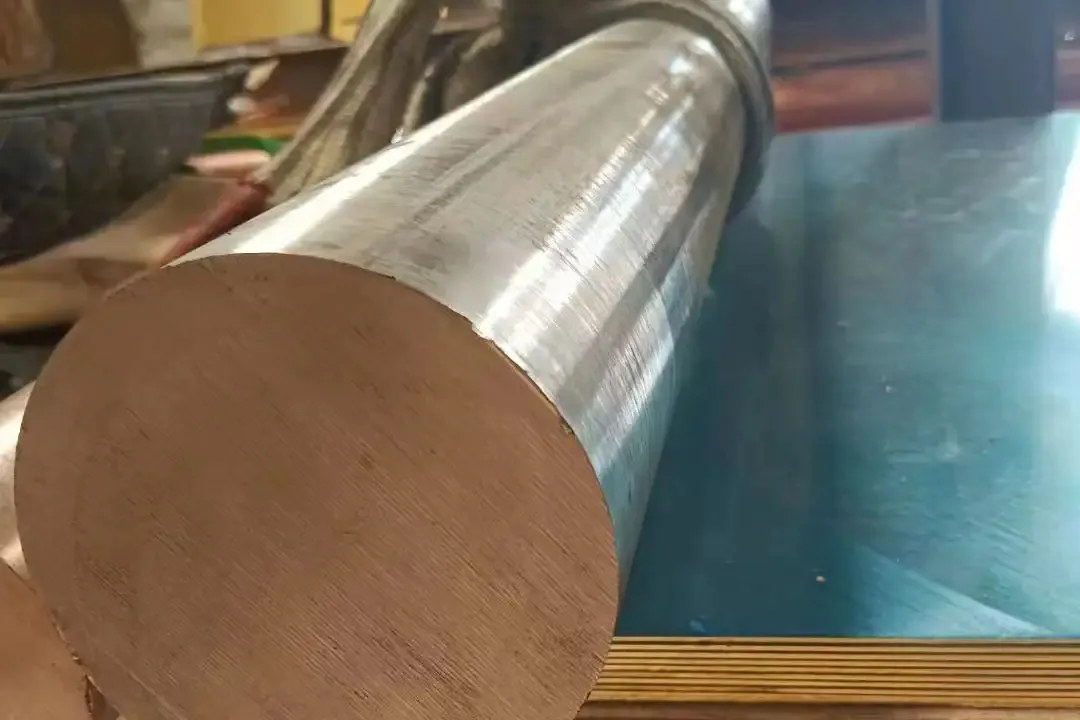

Rods, plates, and sheets for structural and industrial use

Heavy alloy counterweights for aerospace, automotive, and robotics

W–Cu contact materials for electronics, thermal, and electrical systems

Tungsten carbide tools – widely used in machining and drilling

Radiation shielding components for medical equipment and nuclear facilities

Each application requires specific grades, purity levels, and sintering conditions, showcasing PM’s flexibility.

Near-Net Shape Manufacturing – reduces machining and material waste

High Material Utilization – over 95% of the powder is used, promoting sustainability

Precision and Stability – superior dimensional accuracy and repeatability

Complex Geometries Possible – MIM and advanced pressing enable intricate designs

Cost-Effective for High-Melting Metals – avoids expensive melting and casting

PM allows manufacturers to produce parts faster, cheaper, and with higher performance than traditional methods.

Ensuring Quality in Tungsten PM

High-performance industries demand rigorous quality control:

Powder testing (particle size, purity, flowability)

Density and porosity checks for green and sintered parts

Mechanical strength and hardness evaluation

Microstructure analysis (grain size, orientation)

Non-destructive testing for critical applications

For sectors like defense, aerospace, and medical equipment, quality assurance is non-negotiable.

The industry is evolving rapidly:

Finer, more uniform powders for improved microstructure and performance

Integration with additive manufacturing for flexible, on-demand production

Advanced binder systems to enhance shaping precision

Ultra-pure, high-density tungsten alloys for next-gen electronics and aerospace

Recycling tungsten scrap to reduce costs and environmental impact

These innovations ensure tungsten PM remains at the forefront of high-performance and sustainable manufacturing.

Powder metallurgy has redefined tungsten manufacturing, enabling precise, durable, and cost-efficient production. From raw powder preparation to pressing and sintering, each step impacts the component’s performance, reliability, and suitability for extreme conditions.

For engineers and manufacturers seeking high-density, heat-resistant, and wear-resistant materials, tungsten produced via powder metallurgy remains one of the most dependable solutions in modern industry.

Share this page

If you have any product needs or questions, please leave us a message for consultation.

TEL: 86-18623759992

jason@bettmetal.com

Innovating Materials

for a Brighter Future