Titanium has become a premium material in the marine industry—not just because of its strength, but because it offers a unique combination of properties that outperform traditional metals such as steel, aluminum, and copper alloys.

Below are the five enhanced, engineering-backed benefits of using titanium products in modern marine engineering.

Titanium’s most valuable advantage lies in its ability to form a stable, self-healing oxide layer. Even when scratched or exposed to extreme conditions, the oxide film regenerates instantly, preventing:

1) chloride-induced pitting

2) crevice corrosion

3) stress corrosion cracking

4) galvanic corrosion in mixed-metal assemblies

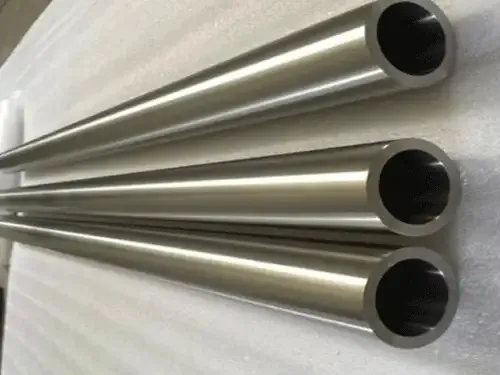

This makes titanium ideal for:

1) seawater piping systems

2) heat exchangers

3) marine fasteners

4) offshore platform components

5) desalination plants

Compared with stainless steel—whose corrosion resistance declines sharply in high-salinity conditions—titanium remains virtually unaffected. This dramatically reduces maintenance frequency, lowers lifecycle cost, and ensures reliable long-term operation.

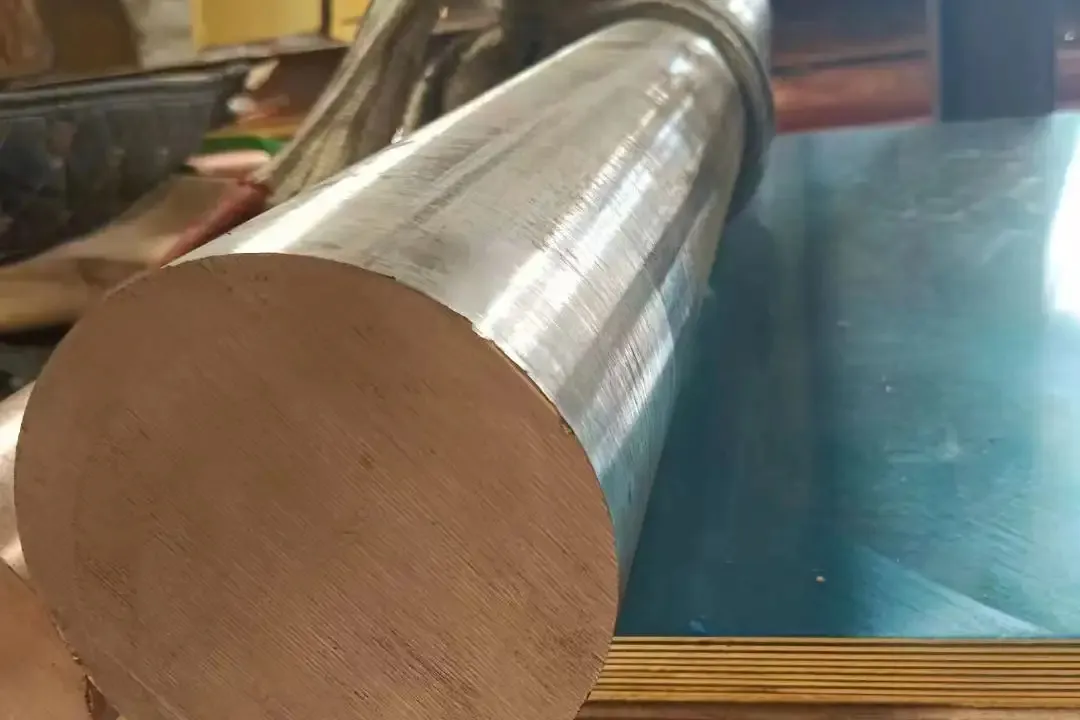

Titanium provides the strength of steel at nearly half the weight, making it a preferred material where both structural integrity and weight reduction matter.

Key performance benefits include:

Better fuel efficiency for ships and marine vessels

Enhanced payload capacity for submersible vehicles

Reduced structural stress on offshore platforms

Improved maneuverability in high-performance marine equipment

For applications such as propeller shafts, hull reinforcements, and underwater robotics, titanium helps engineers achieve superior mechanical performance without compromising safety.

Marine equipment faces repeated cycles of loading, vibration, and impact. Titanium’s excellent fatigue resistance and toughness ensure it performs reliably under:

Dynamic wave forces

High internal pressures

Long-term mechanical stress

Industries leveraging titanium report service lives 2–3 times longer than traditional metal components. This durability translates to:

Lower replacement costs

Fewer unplanned shutdowns

Improved operational continuity

For companies operating in offshore oil & gas, naval engineering, or deep-sea exploration, titanium becomes a strategic investment in operational stability.

Biofouling is one of the biggest problems in marine engineering, causing:

reduced vessel speed

Increased drag and fuel consumption

Impaired pipeline flow

Equipment performance loss

Titanium’s smooth, inert surface offers excellent resistance to the attachment of barnacles, algae, and microorganisms.

Benefits include:

Cleaner hull surfaces

Improved propeller and pump efficiency

Reduced cleaning and anti-fouling coating expenses

Lower environmental impact by minimizing chemical usage

This makes titanium ideal for ship hulls, seawater intake systems, cooling systems, and underwater sensors.

Titanium retains its mechanical performance even under extreme conditions, including:

Deep-sea pressures > 6,000 meters

Rapid temperature fluctuations

High-impact, corrosive offshore environments

As a result, titanium is widely used in:

Deep-sea submersibles & autonomous underwater vehicles (AUVs)

High-pressure housings and valves

Offshore drilling components

Cryogenic and high-temperature marine systems

Where other metals weaken, warp, or corrode, titanium ensures uncompromised reliability.

Titanium products offer a powerful combination of corrosion resistance, lightweight strength, durability, antifouling properties, and extreme-condition performance. For marine engineers and companies striving to improve efficiency, reduce maintenance, and extend the lifespan of critical equipment, titanium represents a material upgrade that delivers long-term ROI.

If your organization is exploring ways to increase reliability and performance in demanding marine environments, investing in titanium components is a proven strategy for long-term success.

Share this page

If you have any product needs or questions, please leave us a message for consultation.

TEL: 86-18623759992

jason@bettmetal.com

Innovating Materials

for a Brighter Future