To prevent a tungsten plate from deforming at high temperatures, you must address the primary mechanisms of high-temperature deformation, namely creep and recrystallization. While tungsten has an exceptionally high melting point (3,422°C), it can still experience deformation at temperatures far below this point.

High Purity Tungsten: The purer the tungsten, the better its high-temperature performance. Impurities can act as sites for grain boundary sliding and void formation, leading to deformation.

Doped Tungsten: For very high temperatures and specific applications, tungsten can be doped with small amounts of elements like potassium, thorium, or rhenium.

Potassium-doped (Non-sag) Tungsten: This is common in lighting filaments. Potassium bubbles form elongated grains that resist creep and deformation at high temperatures.

Rhenium Alloyed Tungsten (W-Re): Adding rhenium significantly improves ductility, tensile strength, and creep resistance at elevated temperatures, though it also increases cost.

Sintering and Consolidation: Proper sintering to achieve high density and uniform grain structure is vital. Residual porosity can lead to deformation.

Thermomechanical Processing (Rolling and Annealing): Carefully controlled rolling schedules followed by annealing can create a preferred grain orientation (texture) and fine grain size, which can enhance creep resistance.

Recrystallization Control: Preventing premature or uncontrolled recrystallization at operating temperatures is key, as recrystallized grains are often softer and more prone to deformation.

Stress Relieving: Prior to high-temperature use, a stress-relieving anneal can remove internal stresses introduced during manufacturing, which might otherwise contribute to deformation.

Thicker Gauges: Where possible, using a thicker tungsten sheet will inherently provide more stiffness and resistance to bending and warping.

Ribs and Stiffeners: Incorporating structural ribs or stiffeners into the design of the tungsten component can significantly enhance its rigidity.

External Support Structures: For larger sheets or components under load, external support made of materials with similar or lower thermal expansion coefficients (if possible) or designed to accommodate differential expansion can help maintain shape.

Distributed Loading: Avoid concentrated loads. Distributing the load evenly across the surface of the tungsten sheet minimizes stress concentrations that could initiate deformation.

Protective Atmosphere/Vacuum: At high temperatures, tungsten can oxidize rapidly in the presence of oxygen, forming volatile oxides that degrade the material and compromise its structural integrity.

Inert Gas (Argon, Nitrogen): Using an inert gas atmosphere prevents oxidation.

Vacuum: A high vacuum is also effective in preventing oxidation and other atmospheric reactions.

Temperature Uniformity: Non-uniform heating can lead to differential thermal expansion and internal stresses, causing warping. Ensuring even heating across the entire tungsten sheet is crucial.

Heating and Cooling Rates: Rapid heating or cooling can induce thermal shock and stresses. Controlled, gradual heating and cooling rates are recommended, especially for thicker sections.

Protective Coatings: While tungsten's high melting point is an advantage, its susceptibility to oxidation at high temperatures can be a challenge. Coatings can provide a barrier.

Silicide Coatings: MoSi2 or WSi2 coatings can form a protective silica layer at high temperatures, offering oxidation resistance. However, their effectiveness is temperature-dependent and can be limited by cracking due to thermal expansion mismatch.

Other Ceramic Coatings: Depending on the specific environment, other ceramic coatings might be considered, though finding coatings that adhere well and match the thermal expansion of tungsten at very high temperatures is difficult.

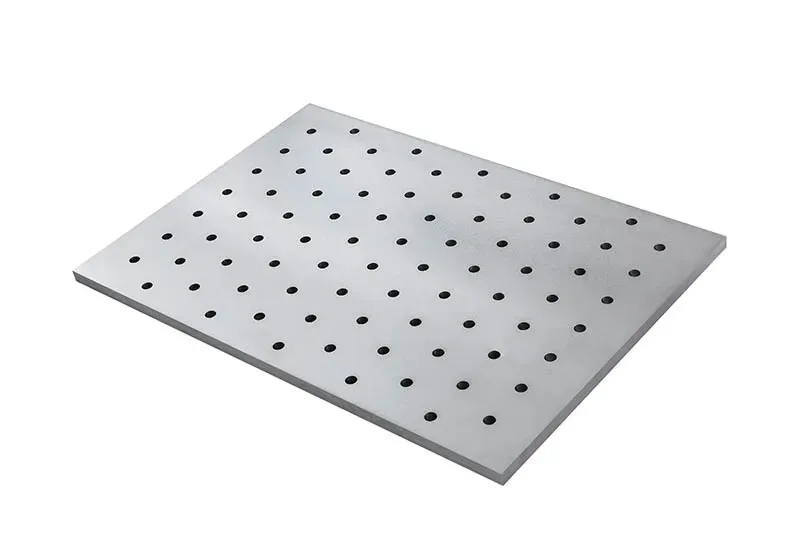

Tungsten plates are widely used in electronics,aerospace, furnace components, and other high-temperature applications due to their extremely high melting point, excellent thermal conductivity, and outstanding wear resistance. However, when exposed to prolonged high temperatures, tungsten plates may face challenges such as warping, oxidation,or deformation, which can reduce performance and shorten service life.

Share this page

If you have any product needs or questions, please leave us a message for consultation.

TEL: 86-18623759992

jason@bettmetal.com

Innovating Materials

for a Brighter Future