This article provides an in-depth overview of why titanium is so vital to aerospace applications, how it compares with other materials, and why global manufacturers continue investing heavily in titanium-based technologies.

The aerospace sector demands materials that can handle extreme stress, wide temperature fluctuations, and harsh operational environments. Titanium stands out because it offers an unmatched blend of:

High mechanical strength

Low density and lightweight performance

Excellent corrosion resistance

Superior thermal stability

Long-term durability

These qualities make titanium products ideal for critical structural and functional aerospace components. In many cases, they offer performance benefits that no other metal—whether aluminum, steel, or nickel alloy—can fully replicate.

As global aviation companies strive to reduce weight, improve fuel efficiency, and adopt more sustainable designs, titanium’s role becomes even more crucial.

One of the most significant advantages of titanium in aerospace is its superior strength-to-weight ratio. While titanium alloys can exhibit strength levels comparable to high-strength steel, they are nearly 45% lighter. This combination helps engineers achieve lighter yet stronger structures, which directly contributes to:

Reduced aircraft weight

Lower fuel consumption

Longer travel ranges

Higher payload capacity

Enhanced maneuverability

2.1 Comparison With Other Aerospace Materials

|

Material |

Density |

Strength |

Corrosion Resistance |

Temperature Resistance |

|

Titanium Alloys |

Low |

Very High |

Excellent |

Excellent |

|

Aluminum Alloys |

Very Low |

Moderate |

Good |

Moderate |

|

Steel |

High |

Very High |

Fair |

High |

|

Nickel Alloys |

Moderate |

Very High |

Excellent |

Very High |

Titanium provides an ideal balance, outperforming aluminum in strength and reducing weight compared to steel and nickel alloys. This material advantage explains why modern aircraft—such as Boeing 787 and Airbus A350—use more titanium components than ever before.

Aerospace components are exposed to demanding environmental conditions, including:

High-altitude humidity

Saline atmospheres near oceans

Jet fuel, lubricants, and hydraulic fluids

Temperature cycling

Continuous mechanical stress

Titanium alloys offer outstanding resistance to corrosion, oxidation, and chemical degradation. Unlike aluminum, which corrodes more easily, or steel, which requires coatings or maintenance to prevent rust, titanium maintains its performance for decades, even in extreme environments.

This corrosion resistance translates to:

Longer component lifespan

Lower maintenance costs

Improved reliability

Safer aircraft operation

For aerospace companies seeking long-term structural stability, titanium products remain the preferred choice.

Many aerospace components—especially those located in or near jet engines—must withstand extreme heat while maintaining structural integrity. Titanium alloys can perform reliably at temperatures reaching 400–600°C, far exceeding the limits of most aluminum alloys.

4.1 Key Applications Requiring High-Temperature Performance

Turbine casings

Engine brackets

Jet engine compressor blades

Exhaust systems

Helicopter rotor hubs

Hypersonic aircraft components

Titanium’s ability to maintain strength and resist thermal fatigue ensures safer and more reliable performance during high-speed or long-duration flights.

Although primarily valued for its structural advantages, titanium also brings additional functional benefits:

5.1 Non-Magnetic Advantage

Titanium is non-magnetic, making it ideal for:

Precision navigation instruments

Avionics systems

Electromagnetic-sensitive environments

Satellite components

In aerospace, even slight magnetic interference can compromise navigation accuracy, making titanium a safe and optimal choice.

5.2 Biocompatibility in Aerospace Crew Equipment

Titanium’s biocompatibility allows it to be used in:

Life-support devices

Crew cabins

Safety equipment

Medical tools used in space missions

Its safety in human-contact applications is especially valuable in long-duration spaceflight missions.

Modern aerospace manufacturers increasingly rely on titanium alloys for both structural and functional components. Some of the most widely used titanium applications include:

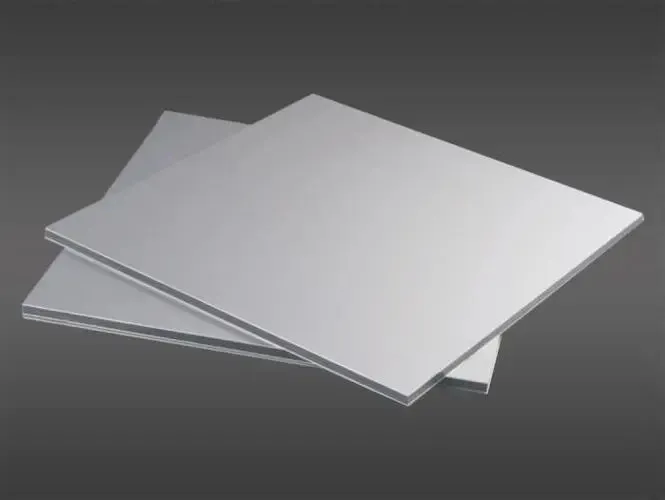

6.1 Airframe and Structural Components

Titanium is commonly used in:

Wing and fuselage structures

Landing gear support beams

Load-bearing airframe parts

High-stress joints and fasteners

Structural brackets

These components must withstand heavy loads while remaining lightweight—making titanium the ideal material.

6.2 Engine and Propulsion Systems

Titanium’s high-temperature performance makes it perfect for:

Turbine blades

Compressor components

Jet engine casings

Engine pylons

Rocket motor housings

In rocket design, titanium alloys help reduce mass while increasing thrust efficiency, contributing to improved payload ratios.

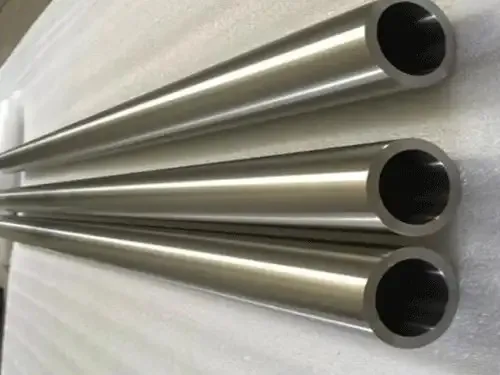

6.3 Spacecraft and Satellite Systems

Titanium’s durability and corrosion resistance are vital in space, where materials face:

Radiation

Extreme temperature shifts

Vacuum conditions

Common titanium uses in space include:

Satellite frames

Deep-space probe structures

Solar array brackets

Space station modules

Titanium ensures long-term performance in harsh extraterrestrial environments.

As aerospace technology continues advancing, titanium’s role is expanding through new manufacturing methods and sustainable innovations.

7.1 Additive Manufacturing (3D Printing)

Titanium is one of the most promising materials for aerospace-grade 3D printing. Additive manufacturing allows companies to:

Reduce material waste

Produce lighter, optimized shapes

Manufacture complex components impossible with traditional machining

Shorten development and production cycles

This technology is already used by major aviation companies for producing engine parts and structural brackets with titanium powder.

7.2 Titanium Composite Materials

New titanium-metal and titanium-polymer composites are being developed to:

Further reduce weight

Enhance fatigue resistance

Improve thermal performance

These advanced composites will power the next generation of high-speed aircraft and reusable spacecraft.

7.3 Sustainability and Fuel Efficiency

Using lightweight titanium components reduces aircraft fuel consumption, which helps:

Cut operating costs

Lower carbon emissions

Improve environmental performance

As global aviation moves toward greener technology, aerospace titanium products will become even more valuable.

Titanium products deliver a rare combination of strength, lightweight performance, corrosion resistance, and thermal stability—qualities essential to aviation safety and efficiency. As aerospace manufacturing shifts toward advanced materials and innovative technologies, titanium alloys will remain central to aircraft, spacecraft, and engine design.

From modern commercial jets to next-generation space exploration vehicles, titanium will continue to play a defining role in making flight safer, more sustainable, and more efficient. For aerospace manufacturers looking to improve performance and reliability, titanium is not just an option—it is the future.

Share this page

If you have any product needs or questions, please leave us a message for consultation.

TEL: 86-18623759992

jason@bettmetal.com

Innovating Materials

for a Brighter Future